| |

|

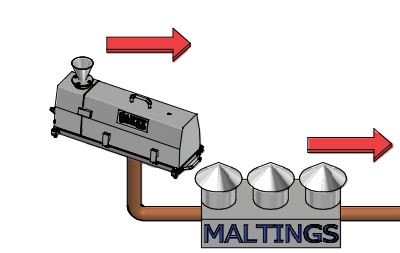

Malting

The size, shape and colour of the cereal grains before and after malting is important for the efficiency of the rest of the brewing process, and also on the quality of product produced. The grains are made to germinate or sprout by soaking in water, and are then halted from germinating further by drying, which develops the enzymes required for the brewing process. The grains are then milled or crushed for easier extraction of sugars during mashing / lautering. The Canty range of SolidSizer™ equipment provides a true 2D dimensional size & shape analysis by analyzing images of the grains, captured by feeding the grain sample between a high intensity light source and camera. Colour analysis can also be provided through use of a second camera / light set up within the same analyser housing. |

Read More

Read More

|

|

|

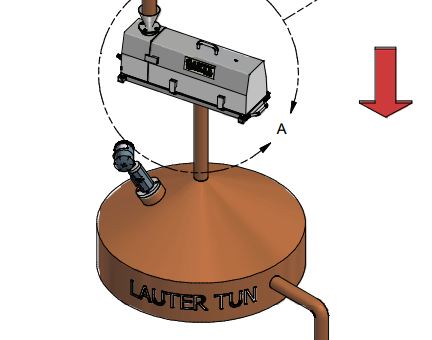

Lauter Tun

Lautering is a process whereby the mash (mixture of malted grain and water) is separated into liquid wort, and residual grain. This is done in a large lauter tun vessel, which essentially is a filter vessel, where the liquid is allowed to pass through the base, while the majority of the solids are retained. Monitoring of lautering process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space on the vessel head, and also ensuring optimum illumination of the area which the operator is viewing. Canty also provide a modular camera light combination unit to provide a remote continuous view of the lauter tun process from the control room. |

Read More

Read More

|

|

|

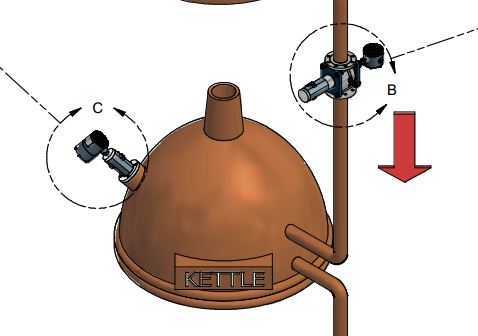

Kettle

Within the kettle, the wort produced by lautering is boiled with hops and sometimes other ingredients such as herbs or sugars. This stage is where many chemical and technical reactions take place, which determine the flavour, colour, and aroma of the beer, so overall is one of the most important steps to monitor withing the brewing prcoess. Monitoring of kettle process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space on the vessel head, and also ensuring optimum illumination of the area which the operator is viewing. Canty also provide a modular camera light combination unit to provide a remote continuous view of the kettle process from the control room. |

Read More

Read More

|

|

|

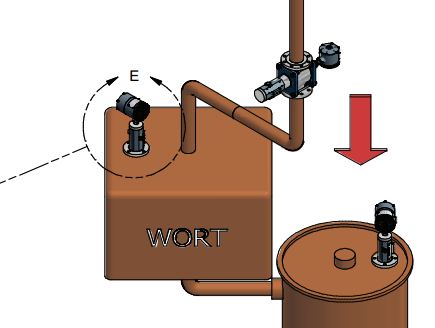

Hot Wort Tank

In the hot wort tank, sometimes called a whirlpool tank, the centrifugal action of the swirling wort causes protein solids known as trub to concentrate in the center of the tank bottom where it can be easier separated from the wort to clarify it before it is cooled. Monitoring of hot wort tank is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space on the vessel head, and also ensuring optimum illumination of the area which the operator is viewing. Canty also provide a modular camera light combination unit to provide a remote continuous view of the hot wort tank from the control room. Between batches the camera can be used to verify that the hot wort tank has been fully cleaned so as to avoid contamination of the product. |

Read More

Read More

|

|

|

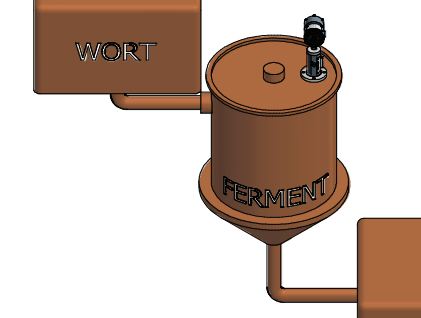

Fermentation

After the wort is cooled and aerated yeast is added to it, and it begins to ferment. It is during this stage that sugars won from the malt are metabolized into alcohol and carbon dioxide, and the product can be called beer for the first time. Monitoring of fermentation process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space on the vessel head, and also ensuring optimum illumination of the area which the operator is viewing. Canty also provide a modular camera light combination unit to provide a remote continuous view of the fermentation process from the control room. The yeast used in fermentation is known as "brewer's yeast" and can be grown onsite at the brewery. Canty's range of liquid particle sizing systems can be used to control the size / concentration of the yeast batches grown, as well as measure yeast cell viability. |

Read More

Read More

|

|

|

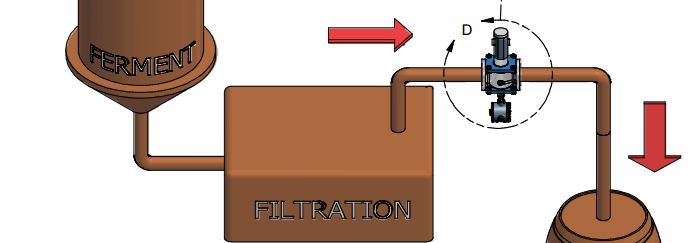

Filtration

Filtering the beer stabilizes the flavour, and gives beer its final taste, colour and consistency. Filters range from rough filters that remove much of the yeast and any solids (e.g., hops, grain particles) left in the beer, to filters tight enough to strain colour and body from the beer. Canty's range of liquid colour and particle sizing systems can be used to monitor the performance of the filter as well as looking for filter breakthrough. |

Read More

Read More

|

|

|

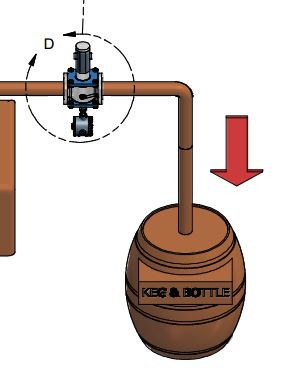

Bottling

The bottling lines are cleaned regularly, so when it comes to pumping beer through once more in order to bottle it, there is a water / beer interface, which if detected efficiently can avoid product wastage and limit the amount of product discharged with the cleaning fluid. Canty provide a direct inline colour analyser, to measure the colour of the fluid to determine if it is water or beer. The image analysis software has the ability to filter out any air bubbles from the analysis, meaning a true colour measurement is performed on the fluid only. |

Read More

Read More

|

|