| |

|

PORTABLE INFLOW™ Oil In Water Analyzer / Water In Oil Analyzer

Document Number: TA11317-1

Detailed Datasheet

•

Read More

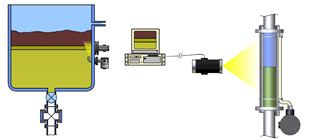

The PORTABLE INFLOW™ Oil In Water Analyzer / Water In Oil Analyzer combining the latest in Ethernet technology with Canty fused glass, lighting and CANTYVISIONCLIENT™ software, the INFLOW™ Process Particle Analyzer provides real time particle size and shape analysis. The Portable Multiphase Meter models measure 0.7 micron - 20,000 micron particles under process conditions. By continuously measuring the product OIL, WATER, SAND, and GAS the OiW / WiO is continually analyzed. This allows the user to see the impact of any change to the refining or drilling system. By using a vision based system CANTY can easily detect all phases and separate them to give PPM/PPB distribution as well as SIZE distribution of all particulates. |

|

|

Process Cameras

Document Number: TA7259-1

Detailed Datasheet

•

Read More

J.M. Canty cameras are patented systems designed to illuminate and view inside a pressure or process vessel through a single connection. There is no need for multiple vessel ports. Canty supplies an integrally mounted camera and lighting system (optional) in a connection as small as a 2” NPT. The industry standard video output can be displayed on a video monitor in the comforts of a control room, or recorded on any VCR. A standard video monitor or TV with video input may be used to display the image. |

|

|

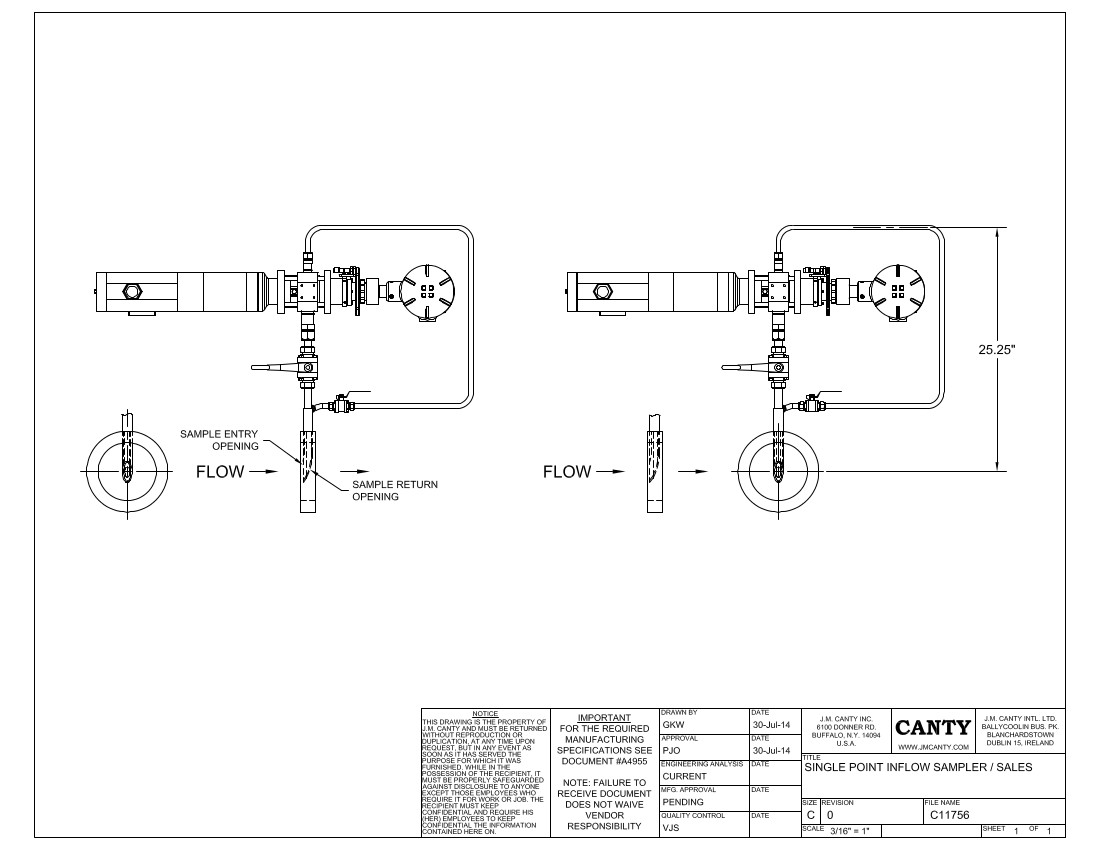

SINGLE POINT INFLOW SAMPLER

Document Number: C11756

Detailed Datasheet

•

Read More

The Canty Single Point Inflow Sampler has been engineered to offer the user a means by which a liquid is analyzed while under varying pressures, temperatures and flow rates. The Single Point Inflow Sampler offers continuous, microscopic, non-destructive viewing and provides multiphase analysis of oil in water, water in oil with two dimensional results. |

|

|

INFLOW™ OIL IN WATER ANALYZER / WATER IN OIL ANALYZER / MULTIPHASE OIL ANALYZER /PRODUCED WATER ANALYZER /OIL SANDS ANALYZER

Document Number: TA11014-1

Detailed Datasheet

•

Read More

The INFLOW™ OIL IN WATER ANALYZER / WATER IN OIL ANALYZER / MULTIPHASE OIL ANALYZER /PRODUCED WATER ANALYZER /OIL SANDS ANALYZER combines the latest in CCD Ethernet camera technology with Canty fused glass, lighting and CANTYVISIONCLIENT™ software, the In-Flow Measurement System provides real time, in-line measurement of oil in water, water in oil, multiphase oil, water and oil sands. |

|

|

PHASE SPLIT

Document Number: TA9788-1

Detailed Datasheet

•

Read More

Monitor phase split in batch mode on organic droplets for increased product recovery. As the droplets appear the system warns of organic phase and the upcoming emulsion. The amount of early droplets and their retraction time will indicate the completeness of the separation. Once the split is identified and stopped, the operator has a visual verification from the video monitor. The color can then be analyzed to ensure there is no inversion. |

|

|

CONTINUOUS INTERFACE CONTROL

Document Number: TA9795-1

Detailed Datasheet

•

Read More

Monitor phase split in batch mode on organic droplets for increased product recovery. As the droplets appear the system warns of organic phase and the upcoming emulsion. The amount of early droplets and their retraction time will indicate the completeness of the separation. Once the split is identified and stopped, the operator has a visual verification from the video monitor. The color can then be analyzed to ensure there is no inversion. |

|