| |

|

Non-Contact Level Control Application Sheet

Document Number: TA7577-1

Detailed Datasheet

•

Read More

An adhesives company had a costly problem with one of it's products with regard to process level control. Due to the viscous, sticky nature, and foaming of the product it coated floats and probes rendering those types of process level control instruments ineffective. DP and ultrasonic devices would not operate during foaming conditions internally. Nuclear devices were not an attractive alternative due to the many regulatory and safety concerns they impose. Operators controlled the process by observing the reactor level out in the plant at various times. This type of control proved grossly inefficient and severely limited process output. |

|

|

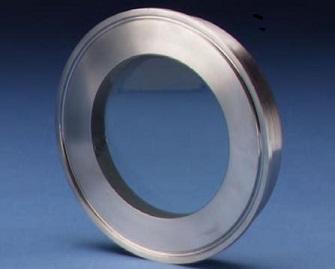

Fuseview™ Tri-Clamp® Sight Glass

Document Number: TA7653-1

Detailed Datasheet

•

Read More

J.M. Canty Fuseview™ sight glasses have been engineered to meet all your process and safety needs. Fuseview™ Tri-clamps® are a fused sight glass providing one-piece construction with no additional gaskets or torquing required. All standard Tri-clamp® Fuseviews™ feature Factory Mutual approval and were designed and tested to ensure the safest product available. Canty can provide certification of material and testing if required, typical of ASME code requirements for process vessels. |

|

|

Pureview™ Sanitary Sight Glass/Lighting System

Document Number: TA9306-1

Detailed Datasheet

•

Read More

Canty fiber optic lighting systems have been designed to provide efficient, high output tungsten-halogen light in a cost effective package. Canty uses only high quality, flexible fiber optic light pipes to guide the light from our light source through a sight glass or process connection. The light is elliptically focused into the fiber optic light pipe and guided through the sight glass minimizing losses while maximizing your tank or vessel lighting! |

|

|

MicroFlow™ Particle Sizing System

Document Number: TA9309-1

Detailed Datasheet

•

Read More

The Canty Microflow has been engineered to offer the user a means by which a liquid is analyzed while under varying pressures, temperatures and flow rates. The Microflow offers sample or continuous, microscopic, non-destructive viewing and provides particle size analysis with two dimensional results when used in conjunction with the Canty Vector System. |

|

|

Process Cameras

Document Number: TA7259-1

Detailed Datasheet

•

Read More

J.M. Canty cameras are patented systems designed to illuminate and view inside a pressure or process vessel through a single connection. There is no need for multiple vessel ports. Canty supplies an integrally mounted camera and lighting system (optional) in a connection as small as a 2” NPT. The industry standard video output can be displayed on a video monitor in the comforts of a control room, or recorded on any VCR. A standard video monitor or TV with video input may be used to display the image. |

|

|

HYL 52 LED Sanitary Lighting System Stainless Steel NEMA 4X Construction

Document Number: TA11500-1007

Detailed Datasheet

•

Read More

**New LED Lighting Systems** The HYL 52 LED lighting system is designed to illuminate bio reactors, fermentors and sanitary vessels. The HYL 52 light is a fused glass light which provides a high intensity, cold light source to allow the process to be viewed under a true white light (3500° K color temperature) while adding no heat to the process, which would cause product bake-on. The HYL 52 lighting package provides a compact, cost effective, maintenance free lighting system to meet all of your sanitary process needs. No more changing bulbs! |

|

|

Aseptic NA-Connect® Fuseview™ Sight Glass

Document Number: TA9805-1

Detailed Datasheet

•

Read More

JM Canty Fuseview™ sight glasses have been engineered to meet all your process and safety needs. NA-Connect® Fuseviews™ are a fused sight glass providing one-piece construction with no additional gaskets or torquing required. All standard NA-Connect® Fuseviews™ were designed and tested to ensure the safest product available. Canty can provide certification of material and testing if required, typical of ASME code requirements for process vessels. |

|