| |

|

EXTREMETEMP™ FURNACE CAMERAS

Document Number: TA10889-1

Detailed Datasheet

•

Read More

Canty High Temperature Cameras are ideal for demanding applications involving visual inspection or verification in extreme temperature environments. |

|

|

ULTRA TEMPERATURE™ CAMERAS

Document Number: TA7355-1

Detailed Datasheet

•

Read More

Canty High Temperature Cameras are ideal for demanding applications involving visual inspection or verification in extreme temperature environments. |

|

|

MINITEMP™ HIGH TEMPERATURE CAMERAS

Document Number: TA7379-1

Detailed Datasheet

•

Read More

Canty Minitemp™ camera systems are a low cost, low maintenance, portable alternative to traditional high temperature cameras. Our unique design allows the unit to be easily moved from location to location in just minutes. |

|

|

FLOAT GLASS WIDTH MEASUREMENTS SYSTEM

Document Number: TA10494-100

Detailed Datasheet

•

Read More

Minimize trim loss – The Canty float glass system consists of a high temperature Ethernet process camera and incorporates special software to reduce glare along with a unique orifice plate that prevents debris from adhering to the lens, resulting in a clear view of the glass ribbon at all times. This system is a non-contact web width control system which positions Ethernet cameras over the two glass edges and provides continuous real time measurement of web width as glass enters the Lehr annealing chamber after exiting the furnace chamber. Width measurements are made in real-time on a continuous basis, with a resolution of .015"*. CantyVision™ Client Software utilizes image based technology to continually track the extreme edge of the glass ribbon and also the edge of the knurled region formed by the top roll machines used in the float bath furnace to shape and stabilize the glass ribbon. |

|

|

TEMPERATURE MEASUREMENTS BY VISION

Document Number: TA10632-1

Detailed Datasheet

•

Read More

Canty’s thermal vision system is quite similar to other radiative temperature methods, by measuring the energy produced by a process. The advancements in CCD cameras has allowed for the ability to measure wavelengths in both the visual range and near inferred range. |

|

|

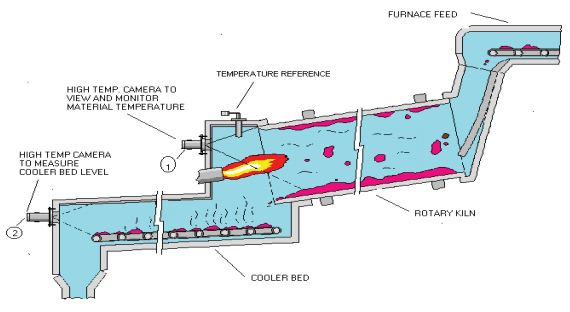

MATERIAL TEMPERATURE/COOLER BED

Document Number: TA7396-1

Detailed Datasheet

•

Read More

The Canty Vision System will monitor product temperature and kiln wall temperatures. The reference rod contains a heat source and a temperature control unit. |

|

|

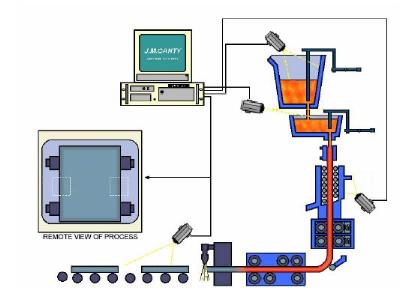

CONTINUOUS CASTER APPLICATION SHEET

Document Number: TA8159-1

Detailed Datasheet

•

Read More

Controlling the cutting process efficiently is critical in a continuous casting process. As the torch carriage rests on the slab it must index the edges mechanically in order to control the movement of the torches. Any error due to mechanical failure can cause incomplete cutting of the slab and a shut down of the line. |

|

|

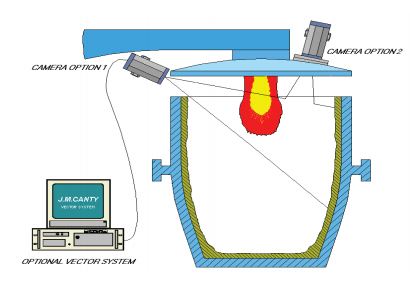

MIXED GAS FLAME MONITORING APPLICATION SHEET

Document Number: TA7616-1

Detailed Datasheet

•

Read More

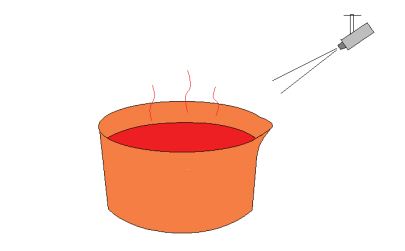

The Canty high temperature camera (option 2), or an Air cooled surveillance camera (option 1) is used to visually monitor the ladle. This image is then sent to the Canty Vector system to sense the flame presence in the zone, and the temperature of the refractory in several other zones. |

|

|

MOLTEN GAS FLAME MONITORING APPLICATION SHEET

Document Number: TA7737-1

Detailed Datasheet

•

Read More

Installation of a Canty Camera and Vector system resolves these problems by providing a rugged camera system that withstands the constant plant conditions and provides a video signal to the Vector which analyzes the temperature through the visible wavelengths and provides an integrated measurement over a large surface area of the metal. Area of analysis is operator selectable. |

|

|

MOLTEN GLASS LEVEL - HIGHTEMP™ SURVEILLANCE CAMERA

Document Number: TA10259-1

Detailed Datasheet

•

Read More

The Canty system consists of a high temperature Ethernet process camera and incorporates special software to reduce glare along with a unique orifice plate that eliminates any debris from adhering to the lens, offering a clear view of the molten level at all times. This new low cost,no-maintenance system replaces expensive traditional platinum dipper probe systems which tendto coat over in a matter of weeks as well as nuclear gauges and eliminates the need for stilling wells. Level measurements are made in real-time on a continuous basis, with a resolution of .002".CANTYVISIONCLIENT™ Software utilizes image based technology to continually track the edge. A crosshair is used to continually indicate the position of the edge and a numerical output is given. What’s more, your results are visually verifiable on your local area network or localized computer! 4-20mA current loop available. |

|