| |

|

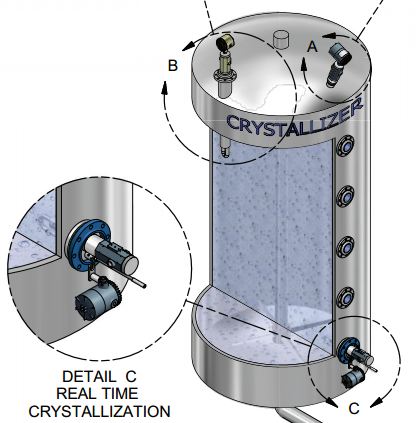

Crystallizer

Manual monitoring of a crystallisation process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space, and also ensuring optimum illumination of the area which the operator is viewing. Remote process monitoring is possible through the use of a microscopic camera system to allow the user to view the growth of the crystals. The Canty Crystalvision™ range combines Canty’s fused glass and lighting technologies to provide an unrivalled continuous view from initial nucleation, to fully formed crystals, allowing for early problem detection (eg. secondary seeding) and reaction. Cantyvision image analysis software allows for particle size and shape characterization during the initial stages of crystal growth (up to 5% concentration), while the remote view is continuos throughout the process. |

Read More

Read More

|

|

|

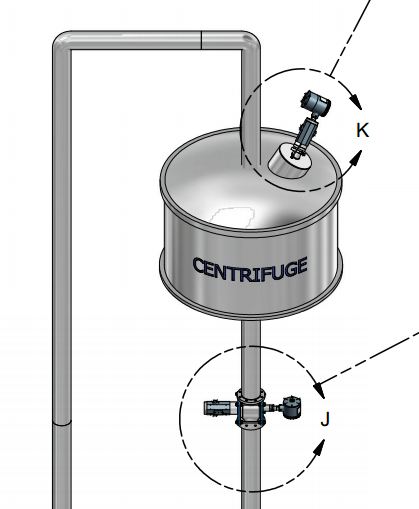

Centrifuge

Monitoring of centrifuge processing (either a batch or continuous) is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space on the vessel head, and also ensuring optimum illumination of the area which the operator is viewing. Canty also provide a modular camera light combination unit to provide a remote continuous view of the centrifuge process from the control room. Cantyvision image analysis software allows for cake thickness measurement and cake colour (used to indicate stage of filtration)" |

Read More

Read More

|

|

|

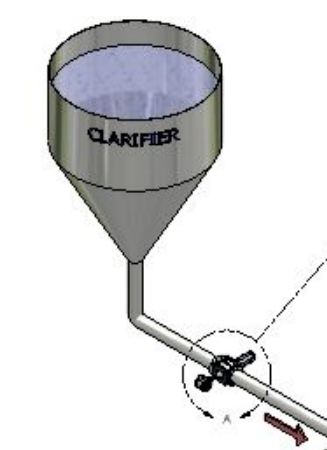

Clarifier

Canty provide a direct inline colour & turbidity analyser, to analyse the fluid discharged from the clarification process, in order to determine if it is within specification. Combining Canty’s imaging, fused glass and lighting technologies, the colour of the liquid can be analysed on a number of colour scales (YUV, RGB, Lab), which can be taken as a direct measurement, or related to a specific NTU or FTU turbidity value. The image analysis software has the ability to filter out any air bubbles from the analysis, meaning only a true colour / turbidity measurement is performed on the fluid. |

Read More

Read More

|

|

|

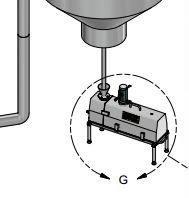

Solids Handeling

The final product may be transferred to storage / packaging by means of conveyor belt. In order to know the quantity of product produced, it is important to have an accurate volume measurement. Traditionally, volume belt scales are used, but there can be significant time spent on maintenance of this equipment due to the nature of how the measurement is performed. The Canty Volume Flow system is a non contact visual measurement of the product area profile on the end of the conveyor. This area measurement can be combined with the velocity of the belt (separate measurement required) in the operators control system, to provide an accurate volume flow measurement. |

Read More

Read More

|

|