Overview

|

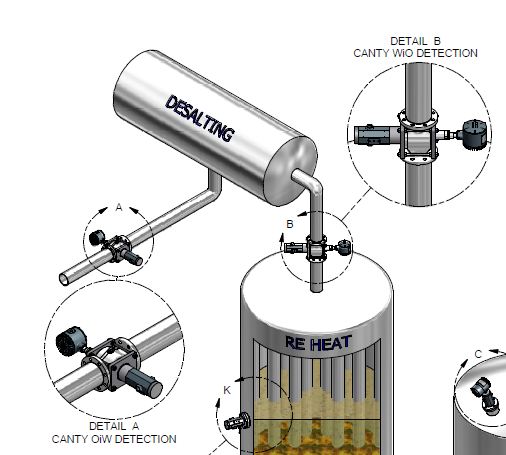

Canty specializes in many applications for the desalters, to include oil in water, water in oil, and liquid interface detection. |

Features

• PPM measurement down to 1PPM

• Visual verification of materials within line, along with size, shape, and color measurements

• NEMA 4, IP66, Explosion proof (Class I, Div. 1, Group B, C & D, Class II, Div. 1, Groups E, F & G) or Flameproof EEx d IIC T6 Ratings