| |

|

HYL Series 50W, 80W Fiber Optic Flex Bundle Lighting Systems

Document Number: TA10607-1

Detailed Datasheet

•

Read More

Canty fiber optic lighting systems have been designed to provide efficient, high output tungsten-halogen light in a cost effective package. Conventional methods of lighting through a sightglass are ineffective since a majority of the light is reflected off of the sightglass. Canty uses only high quality, flexible fiber optic light pipes to fiber-optically guide the light from our light source through a sightglass or process connection. The light is elliptically focused into the fiber optic light pipe and guided through the sightglass, minimizing losses while maximizing your tank or vessel lighting! |

|

|

Process Cameras

Document Number: TA7259-1

Detailed Datasheet

•

Read More

J.M. Canty cameras are patented systems designed to illuminate and view inside a pressure or process vessel through a single connection. There is no need for multiple vessel ports. Canty supplies an integrally mounted camera and lighting system (optional) in a connection as small as a 2” NPT. The industry standard video output can be displayed on a video monitor in the comforts of a control room, or recorded on any VCR. A standard video monitor or TV with video input may be used to display the image. |

|

|

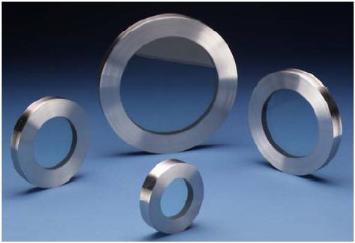

Fuseview ™ ANSI/DIN Sight Glass

Document Number: TA7652-1

Detailed Datasheet

•

Read More

J.M. Canty Fuseview™ sight glasses have been engineered to meet all your process and safety needs. All standard Fuseviews™ feature Factory Mutual approval and were designed and tested to ensure the safest product available. Canty can provide certification of material and testing if required, typical of ASME code requirements for process vessels. |

|

|

INFLOW™ PARTICLE SIZING SYSTEM

Document Number: TA10601-1

Detailed Datasheet

•

Read More

Combining the latest in Ethernet technology with Canty fused glass, lighting and CANTYVISIONCLIENT™ software, the In-Line Process Particle Analyzer provides real time particle size, shape, color, and percent solid analysis. |

|