| |

|

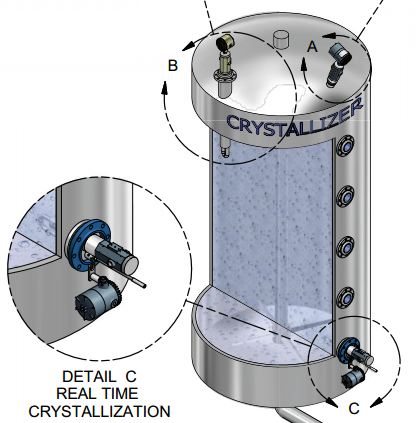

Crystallizer

Manual monitoring of a crystallisation process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space, and also ensuring optimum illumination of the area which the operator is viewing. Remote process monitoring is possible through the use of a microscopic camera system to allow the user to view the growth of the crystals. The Canty Crystalvision™ range combines Canty’s fused glass and lighting technologies to provide an unrivalled continuous view from initial nucleation, to fully formed crystals, allowing for early problem detection (eg. secondary seeding) and reaction. Cantyvision image analysis software allows for particle size and shape characterization during the initial stages of crystal growth (up to 5% concentration), while the remote view is continuos throughout the process. |

Read More

Read More

|

|

|

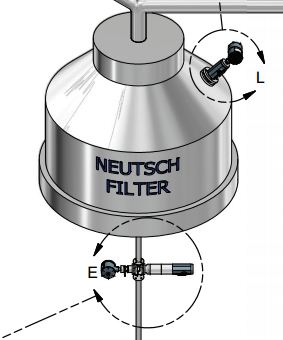

Filtration

Monitoring of a filtration process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space on the vessel head, and also ensuring optimum illumination of the area which the operator is viewing. Canty also provide a modular camera light combination unit to provide a remote continuous view of the filtration process from the control room. Cantyvision image analysis software allows for automatic detection of the filtration end point (transition from liquid to solid "cake") which avoids cracking of the cake, and allows for an efficient wash cycle. |

Read More

Read More

|

|

|

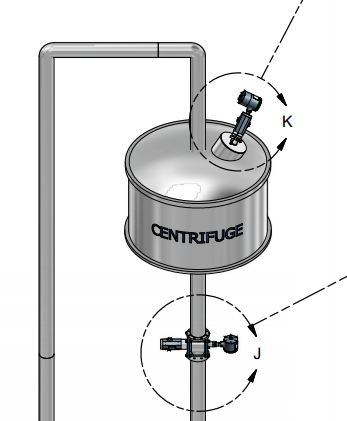

Centrifuge

"Monitoring of centrifuge processing (either a batch or continuous) is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space on the vessel head, and also ensuring optimum illumination of the area which the operator is viewing. Canty also provide a modular camera light combination unit to provide a remote continuous view of the centrifuge process from the control room. Cantyvision image analysis software allows for cake thickness measurement and cake colour (used to indicate stage of filtration)" |

Read More

Read More

|

|

|

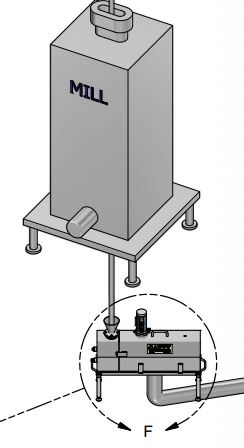

Blending & Milling

Milling & Blending of chemical powders is one of the most basic but most difficult processes to control, with formulations containing any number of different ingredients or components. The individual milled ingredients, and the final blended product needs to be subjected to quality control in order to determine if the particles are the correct size and shape, and also that the concentration of black or discoloured particles is within specification. Canty’s range of image based particle analysis systems provide true size and shape characterisation, with each particle measured under 13 size and shape parameters. Canty’s imaging systems also offer the option of Black Speck detection within the sample. The systems can be run at line through the use of a sweep sampler, or offline as laboratory instruments. |

Read More

Read More

|

|

|

Fluid Bed Dryer

"Monitoring of spray drying process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space on the vessel and also ensuring optimum illumination of the area which the operator is viewing (typcially the area of interest is the spray nozzles to monitor spray angle, check for blockage / ""bearding"". Canty also provide a modular camera light combination unit to provide a remote continuous view of the spray drying process from the control room. Cantyvision image analysis software allows for the measurement of the spray angle as well as automated detection of nozzle blockages." |

Read More

Read More

|

|