| |

|

HYL Series 50W, 80W Fiber Optic Flex Bundle Lighting Systems

Document Number: TA10607-1

Detailed Datasheet

•

Read More

Canty fiber optic lighting systems have been designed to provide efficient, high output tungsten-halogen light in a cost effective package. Conventional methods of lighting through a sightglass are ineffective since a majority of the light is reflected off of the sightglass. Canty uses only high quality, flexible fiber optic light pipes to fiber-optically guide the light from our light source through a sightglass or process connection. The light is elliptically focused into the fiber optic light pipe and guided through the sightglass, minimizing losses while maximizing your tank or vessel lighting! |

|

|

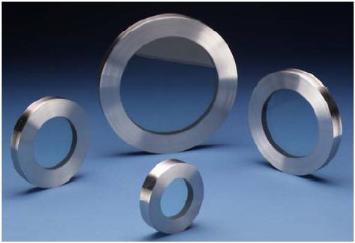

Fuseview ™ ANSI/DIN Sight Glass

Document Number: TA7652-1

Detailed Datasheet

•

Read More

J.M. Canty Fuseview™ sight glasses have been engineered to meet all your process and safety needs. All standard Fuseviews™ feature Factory Mutual approval and were designed and tested to ensure the safest product available. Canty can provide certification of material and testing if required, typical of ASME code requirements for process vessels. |

|

|

Lab Reactor

Document Number: VD10353-100

Detailed Datasheet

•

Read More

Canty Glass Reactor Microscope is unique in that it provides the only inline microscopy system that can be calibrated in situ down to .3um (.7um vis). It provides 2D analysis, concentration and visual verification in a single instrument. Current technology has required multiple probes which have measured random chord length, which give less than 1D results and require a separate probe for viewing which has poor resolution and negligible imaging software. The GRM provides data according to the ASTM E29 and ISO standards and readily correlates to other PSM systems. |

|

|

SUGARSCOPE™ PARTICLE SIZING SYSTEM

Document Number: TA10897-1

Detailed Datasheet

•

Read More

The CANTY SUGARSCOPE™ is a high speed video system that captures and displays live video images of sugar crystals in a sugar pan under process conditions for blur-free, flicker-free process monitoring. The SUGARSCOPE™ features a unique, high magnification lens that views particles as small as 1 micron, manual zoom controls to widen the view angle to 1000 microns. No sampling is required - the process is continually monitored under pressure and temperature. |

|