| |

|

GLASS APPLICATIONS

Document Number: TA10103-1

Detailed Datasheet

•

Read More

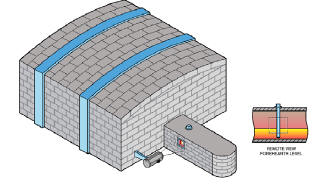

Canty High Temperature insertion cameras are ideal for demanding applications such as glass furnaces involving visual inspection or verification in extreme temperature environments. |

|

|

ULTRA TEMPERATURE™ CAMERAS

Document Number: TA7355-1

Detailed Datasheet

•

Read More

Canty High Temperature Cameras are ideal for demanding applications involving visual inspection or verification in extreme temperature environments. |

|

|

FLOAT GLASS WIDTH MEASUREMENTS SYSTEM

Document Number: TA10494-100

Detailed Datasheet

•

Read More

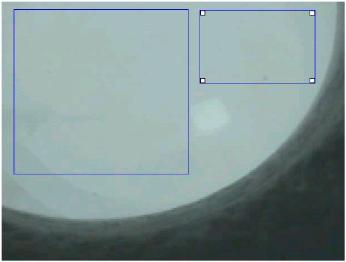

Minimize trim loss – The Canty float glass system consists of a high temperature Ethernet process camera and incorporates special software to reduce glare along with a unique orifice plate that prevents debris from adhering to the lens, resulting in a clear view of the glass ribbon at all times. This system is a non-contact web width control system which positions Ethernet cameras over the two glass edges and provides continuous real time measurement of web width as glass enters the Lehr annealing chamber after exiting the furnace chamber. Width measurements are made in real-time on a continuous basis, with a resolution of .015"*. CantyVision™ Client Software utilizes image based technology to continually track the extreme edge of the glass ribbon and also the edge of the knurled region formed by the top roll machines used in the float bath furnace to shape and stabilize the glass ribbon. |

|

|

Industrial SolidSizer™ Particle Analysis System

Document Number: TA10743-100

Detailed Datasheet

•

Read More

The JM Canty Industrial SolidSizer™ is a vision-based particle size measurement in a production environment as an on-line production tool. |

|

|

TEMPERATURE MEASUREMENTS BY VISION

Document Number: TA10632-1

Detailed Datasheet

•

Read More

Canty’s thermal vision system is quite similar to other radiative temperature methods, by measuring the energy produced by a process. The advancements in CCD cameras has allowed for the ability to measure wavelengths in both the visual range and near inferred range. |

|

|

MOLTEN GLASS LEVEL - HIGHTEMP™ SURVEILLANCE CAMERA

Document Number: TA10259-1

Detailed Datasheet

•

Read More

The Canty system consists of a high temperature Ethernet process camera and incorporates special software to reduce glare along with a unique orifice plate that eliminates any debris from adhering to the lens, offering a clear view of the molten level at all times. This new low cost,no-maintenance system replaces expensive traditional platinum dipper probe systems which tendto coat over in a matter of weeks as well as nuclear gauges and eliminates the need for stilling wells. Level measurements are made in real-time on a continuous basis, with a resolution of .002".CANTYVISIONCLIENT™ Software utilizes image based technology to continually track the edge. A crosshair is used to continually indicate the position of the edge and a numerical output is given. What’s more, your results are visually verifiable on your local area network or localized computer! 4-20mA current loop available. |

|