| |

|

HYL Series 50W, 80W Fiber Optic Flex Bundle Lighting Systems

Document Number: TA10607-1

Detailed Datasheet

•

Read More

Canty fiber optic lighting systems have been designed to provide efficient, high output tungsten-halogen light in a cost effective package. Conventional methods of lighting through a sightglass are ineffective since a majority of the light is reflected off of the sightglass. Canty uses only high quality, flexible fiber optic light pipes to fiber-optically guide the light from our light source through a sightglass or process connection. The light is elliptically focused into the fiber optic light pipe and guided through the sightglass, minimizing losses while maximizing your tank or vessel lighting! |

|

|

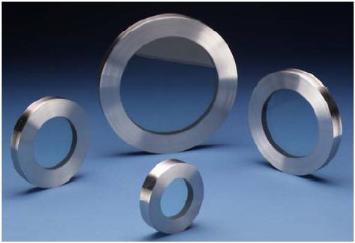

Fuseview ™ ANSI/DIN Sight Glass

Document Number: TA7652-1

Detailed Datasheet

•

Read More

J.M. Canty Fuseview™ sight glasses have been engineered to meet all your process and safety needs. All standard Fuseviews™ feature Factory Mutual approval and were designed and tested to ensure the safest product available. Canty can provide certification of material and testing if required, typical of ASME code requirements for process vessels. |

|

|

CENTRIFUGE CAMERA CONTROL

Document Number: TA9618-1

Detailed Datasheet

•

Read More

The Canty Camera / Light combination is tri-clamp® mounted on to the existing light or sight port of the centrifuge to allow continuous internal viewing from the control room. In the control room, the Vector™ image processing computer will analyze this view and provide a 4-20mA output of fill level, filtering level, and a separate cake (solids) detection signal. The level control allows for consistent batching to the centrifuge. The cake detection 4-20mA output signal provides for immediate detection of solids, which prevent the cake fromcracking. This means higher product yield due to fewer washes, and ultimately better product quality. |

|

|

INFLOW™ TURBIDITY / COLOR ANALYSIS / PERCENT SOLIDS MEASUREMENT SYSTEMS

Document Number: TA10591-1

Detailed Datasheet

•

Read More

The CANTY In-Line Turbidity, Color Measurement or Percent Solids Measurement System uses a 0-1” variable insertion measurement gap, which is unique to the Canty system. This insertion is made possible by the Fuseview™ sight glass, which allows the optical fused pieces to be located in the center of the fluid stream. This provides the highest velocity, most representative profile and automatically flushes the fused glass even in the harshest of environments. |

|